Sintered Stainless Steel Mesh Filter Cylinders and Housing in 304 and 316L

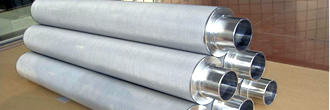

Sintered stainless steel mesh filter element is the chief type of sintered filters, made of choice ss 304 or 316 material.

As suppliers, we can provide reliable, high-performance sintered stainless steel filters with various specifications, material composition, structurals for various industrial uses.

Sintered stainless steel filters combines precision, durability, and a high level of customization in one, ideal for filtration of liquids and gases, supplied in cylindrical cartridges that may be several feet long and several inches in diameter.

Why SS 316 L Material

Sintered filter elements made from 316L stainless steel is durable, also highly resistant to corrosion, making it suitable for various chemical and industrial environments.

Why Sintered Stainless Steel Mesh Filters? - Structures and Features

304 and 316L stainless steel ensures that the structure has high tensile strength and corrosion resistance;

The sintered mesh nature allows for a uniform pore size distribution and precision filtration.

Application

Sintered SS mesh filter elements have a wide range of applications, including but not limited to:

- Chemical processing for the filtration of aggressive chemicals.

- Food and beverage industries where high levels of purity are required.

- Pharmaceutical manufacturing for ensuring product integrity.

- Petrochemical and oil & gas industries for liquid and gas separation.

- Water treatment facilities for removing fine particulates.

Classification

We can supply sintered stainless steel filter elements classified based on:

- Pressure Handling Capability: High-pressure, medium-pressure, and low-pressure variants.

- Filtration Efficiency: Available in various ratings depending on the pore size.

- Form Factor: Cylindrical, conical, disc-shaped, etc.

- Application-specific: Pharmaceutical-grade, food-grade, industrial-grade, etc.

Products Range

Product range varies from ½" to 3" including ½", 1", 1.5".

Technical Requirements:

1) Filter of filtration sizes: 10 micron, 20micron, 40 microns

2) Collapse pressure: To be specified

3) Operating pressure of filter elements: 420 bar maximum and 1 bar minimum

4) Viton seals in the top with temperature resistance of -50 deg C to + 200deg C

5) Material: Stainless steel 316L with Viton seals

6)

Working Medium: Gas

| SINTERED SS FILTER ELEMENT SPECIFICATION LIST | ||||

| SL. NO | PART NO. | DESCRIPTION | FILTRATION RATING | TEMPERATURE RESISTANCE |

| 1 | 12-57-SMF10 | Sintered Stainless Steel Filter Element | 10µm | -50 deg C to + 200deg C |

| 2 | 12-57-SMF20 | Sintered Stainless Steel Filter Element | 20µm | -50 deg C to + 200deg C |

| 3 | 12-57-SMF40 | Sintered Stainless Steel Filter Element | 40µm | -50 deg C to + 200deg C |

| 4 | 25-64-SMF10 | Sintered Stainless Steel Filter Element | 10µm | -50 deg C to + 200deg C |

| 5 | 25-64-SMF20 | Sintered Stainless Steel Filter Element | 20µm | -50 deg C to + 200deg C |

| 6 | 25-64-SMF40 | Sintered Stainless Steel Filter Element | 40µm | -50 deg C to + 200deg C |

| 7 | 38-152-SMF10 | Sintered Stainless Steel Filter Element | 10µm | -50 deg C to + 200deg C |

| 8 | 38-152-SMF20 | Sintered Stainless Steel Filter Element | 20µm | -50 deg C to + 200deg C |

| 9 | 38-152-SMF40 | Sintered Stainless Steel Filter Element | 40µm | -50 deg C to + 200deg C |

| 10 | 51-476-SMF10 | Sintered Stainless Steel Filter Element | 10µm | -50 deg C to + 200deg C |

| 11 | 51-476-SMF20 | Sintered Stainless Steel Filter Element | 20µm | -50 deg C to + 200deg C |

| 12 | 51-476-SMF40 | Sintered Stainless Steel Filter Element | 40µm | -50 deg C to + 200deg C |

Product Illustrations

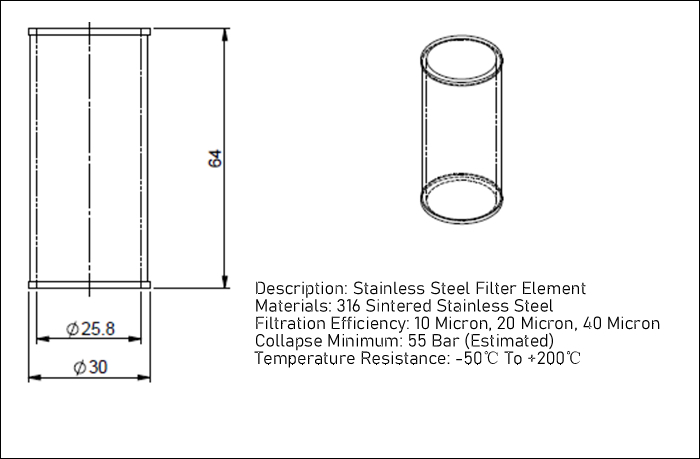

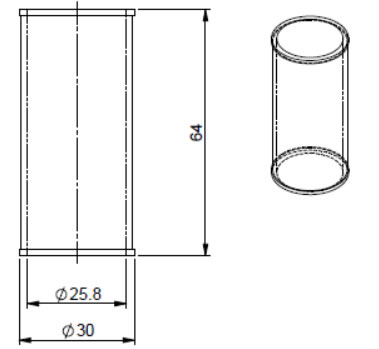

25-64-SMF10 Sintered Stainless Steel Mesh Filter Cylinder

Filtration: 10 micron

Cylinder size: Inner diameter 25.8 x Length 64

As below:

Description: Stainless Steel Filter Element

Materials: 316 Sintered Stainless Steel

Filtration Efficiency: 10 Micron, 20 Micron, 40 Micron

Collapse Minimum: 55 Bar (Estimated)

Temperature Resistance: -50℃ To +200℃

38-152-SMF20 Sintered Stainless Steel Mesh Filter Cylinder

Filtration: 20 micron

Cylinder size: Inner diameter 38 x Length 152

As below:

Sintered Filters

Description: Stainless Steel Filter Element

Materials: 316 Sintered Stainless Steel

Filtration Efficiency: 10 Micron, 20 Micron, 40 Micron

Collapse Minimum: 55 Bar (Estimated)

Temperature Resistance: -50℃ To +200℃

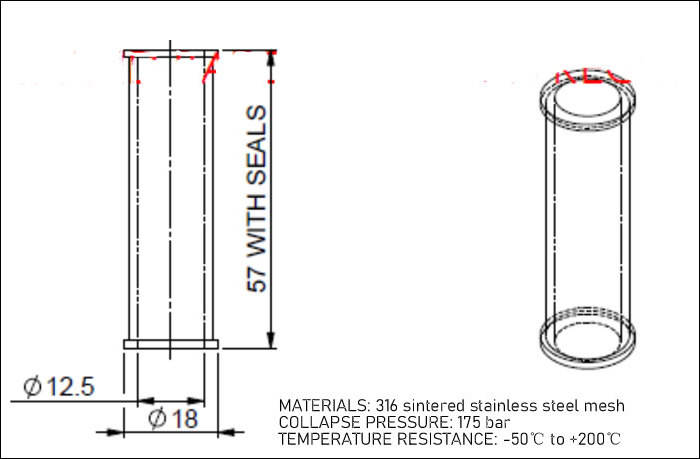

12-57-SMF40 Sintered Stainless Steel Filter Element

Filtration 40 Micron

Cylinder size: ID (inner diameter) 12.5 x length 57 including seals

MATERIALS: 316 sintered stainless steel mesh

COLLAPSE PRESSURE: 175 bar

TEMPERATURE RESISTANCE: -50℃ to +200℃

SS304 Sintered Element Filter with Housing for Fluid Filtration

Element Material: SS-304

Housing Material:SS-304

P-Operating: 2.86 bar

P-Designing: 6.50 bar

Working Fluid: Water

T-Working: 50 ℃

T-Design: 100 ℃

Q-Normal: 1.5 m3/hr.

Q-Max: 2 m3/hr.

ΔP-Normal: .1 to .15 bar

ΔP-Max: 0.70 bar

Particle Size: 40 micron

Inlet size: 01 inches

Outlet sizes: 01 inches

End Connection: Flanged

Removable SS 304 Sintered Element Filter with Housing Element

Material: SS-304

Housing Material:SS-304

P-Operating: 3.20 bar

P-Designing: 6.50 bar

Working Fluid: Water

T-Working: 50 ℃

T-Design: 100 ℃

Q-Nomial: 4.0 m3/hr.

Q-Max: 5.0 m3/hr.

ΔP-Normal: .15 to .25 bar

ΔP-Max: 0.70 bar

Particle Size: 40 micron

Inlet size: 01 inches

Outlet sizes: 01 inches

End Connection: Flanged

To Specify Sintered Stainless Steel Filter Element:

Typical parameters to specify a sintered stainless steel filter element could include:

- Outer Diameter (OD): Measured in millimeters or inches, depending on the system.

- Inner Diameter (ID): Also measured in millimeters or inches.

- Length: For cylindrical filter elements, lengths of 10 inches or 20 inches are common, custom lengths are also available.

- Pore Size: Measured in microns, this indicates the smallest particle size that the filter can effectively remove. Typical values might range from 0.2 to 100 microns.

- Filtration Efficiency: This is usually a percentage that indicates the effectiveness of the filter at removing particles of a certain size.

- Material: Stainless steel can be different grades (304, 304L, 316, 316L) depending on the requirements of the application.

- End Caps/Fittings: SS.

- Flow Rate: Measured in gallons per minute (GPM) or liters per minute (LPM), depending on the filter's pore size, length, and diameter.

- Working Pressure: in (PSI) or bar, indicating the maximum pressure the filter can safely withstand.

- Temperature Range: Indicates the range of temperatures the filter can operate under.

- Surface Area: Greater surface area generally means greater filtration capacity.

- Filtration Rating: A range of filtration ratings can be provided to meet specific application demands.

- Collapse Pressure (min.): Defined according to the application and structural design. This ensures that the filter can withstand the minimum pressure requirements of a given application.

Products List

Stainless Steel Wedge Wire Water Well Screen

Stainless Steel Wedge Wire Water Well Screen