Coating Filter Element for Top Coat Final Filter Station

We supply and help design effective filtration system facilitating optimum product quality in manufacturing or ensuring the purity of substances in chemical processes. Our coating filter system promises not only efficiency but also durability and reliability.

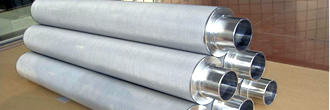

Coating Filter Element manufactured from choice stainless slotted screen material meets the high demands of coating industries.

Material:

SS-316.

Filtration rating: Coating filter element in 150 microns slotted screen

Type: Slotted Screen Filter

What is Top Coat Final Filter Station?

Top Coat Final Filter Station in coating and finishing processes is the filtering system used in the final stages of applying a top coat to a surface in manufacturing or industrial settings.

A final filter station or system serves to ensure the purity and quality of the topcoat being applied, by removing impurities or contaminants from the coating material before it is applied to the product. This process ensures a smooth, clean, and high-quality finish on the final product.

How Does Coating Filter Element Work?

- A coating filter element is used in industrial or manufacturing, where liquid coating materials such as paint, varnish, or other surface treatment substances are applied to products. The coating filter element serves to remove impurities, contaminants, or unwanted particles from the coating material to ensure a smooth, high-quality finish on the coated surface.

- Before the coating material reaches the application equipment, it passes through the filter element, which traps and removes unwanted particles and contaminants. This ensures that the coating material is clean and pure before being applied.

- Coating filter elements are typically designed to be compatible with a wide range of coating materials. They are constructed using materials that resist the chemicals found in coatings.

Different Types of Coating Filter Elements

Bag filters, cartridge filters, basket filters, etc.

Can be custom designed for specific filtration requirements and different types of coating materials.

316 SS Slotted Screen Coating Filter Element: Quality and Efficiency in Filtration

Why Choose Us?

We supply quality Coating Filter Element:

The quality of the coating filter element and its effectiveness in removing impurities directly affects the quality of the final coated product. A good filter element will result in a smoother finish with fewer defects.

We supply Cost Efficiency Filter Elements:

By ensuring a cleaner coating material, the coating filter element helps in reducing the wastage and the need for rework, thus contributing to cost efficiency in the coating process.

The choice of the right coating filter element play a significant role in the coating process, impacting both the quality of the final product and the efficiency of the production process.

Coating Filter Element for Top Coat Final Filter Station and Various Coating Filter System

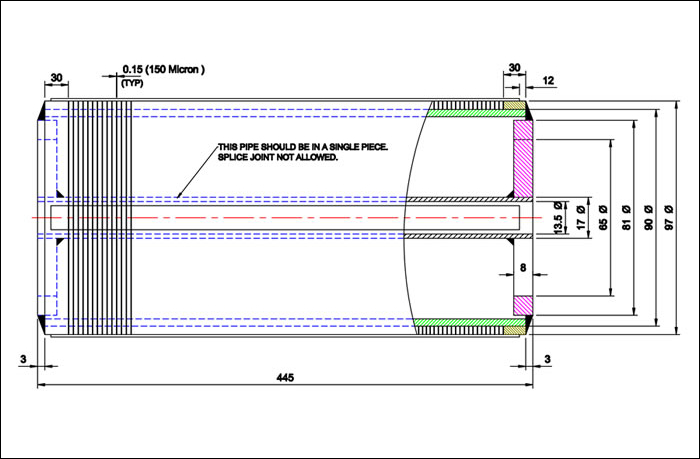

Coating Filter Element in 150 micron

Slotted screen filter element, with a 150-micron screen. The fine screen ensures the separation of particles down to 150 microns in size, thus securing a high degree of purity in the final output at the top coat final filter station. Used for powder and other coating system.

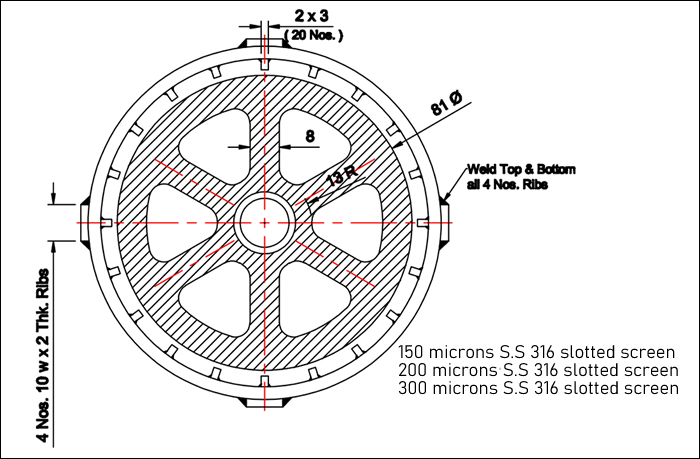

Screen Materials - SS 316 - (in 150 microns, 200 microns, 300 microns, etc)

The material of construction (MOC) for the coating filter element is SS-316, known for its superior corrosion resistance and strength. The choice of Stainless Steel 316 grade makes this filter element not only durable but also resilient in varied operating conditions. Its resistance to pitting and corrosion ensures that the filter remains unaffected by chemicals, providing a long-lasting solution for coating filtration needs.

Structures

The structural integrity of the slotted screen filter is characterized by its complex yet highly effective design. The core of the filter consists of a precisely engineered slotted screen, which forms the main filtration medium. The slots are designed meticulously to ensure uniformity in filtration, preventing the passage of unwanted particles. The surrounding structure, made of SS-316, provides a robust framework that holds the screen in place, facilitating easy installation and removal during maintenance or replacement.

Applications

Slotted screen filter finds its application in the final stages of filtration processes named as the top coat final filter station, to remove fine impurities and achieve a high degree of product purity.

Stainless steel 316 filter elements are used in coating material filtration:

Chemical Resistant Coatings;

High-temperature Coatings;

Solvent-based Coatings;

Marine and Industrial Coatings (In marine and harsh industrial environments where coatings need to withstand saltwater, chemical exposure, or other corrosive elements, stainless steel 316 filter elements can be employed to ensure the purity and quality of the coating materials.);

Food-grade or Pharmaceutical Coatings;

Epoxy Coatings.

Products List

Stainless Steel Wedge Wire Water Well Screen

Stainless Steel Wedge Wire Water Well Screen