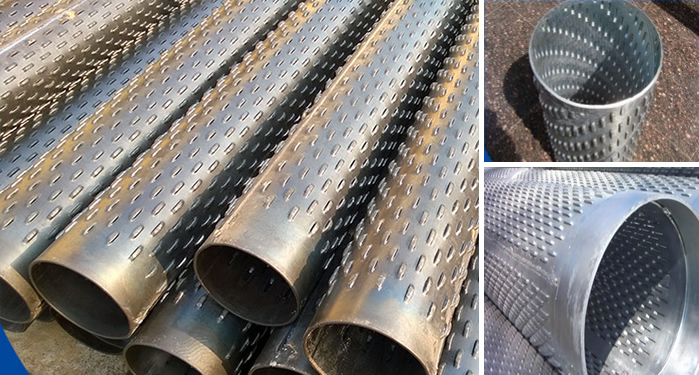

Perforated Tube Sand Control Screen - Well Sand Filter Elements

Sand Filter Element is manufactured from stainless perforated tube used for vertical wells, the inclined shaft, horizontal wells and various gas, oil and water well screen, as anti-sand filter blocks.

Sand Control Filter Tube/ Casing Pipe for Water Well Screen

Perforated Tubes / pipes can be used for vertical wells, the inclined shaft, horizontal wells and various gas, oil and water wells. Can be used individually as sand control tube, also can be used together with filling. Hengmao offers two types of perforated tubes for sand control in well screen development. One is bridge slotted tube, the other is perforated round hole welded tube.

Bridge Slotted Perforated Tube has openings arranged in rows are staggered to reduce the negative effect on the screen’s strength. Regarded as the best choice of well tube filter, bridge slotted pipe screens are widely applied in oil well and water well drilling fields in the developed countries,whichis Russia, Iraq, Algeria, India,South Africa ,ect.

Specification of Slotted Brige Casing Pipe

| Diameter (mm) | 146 | 159 | 219 | 273 | 325 | 377 | 426 | 529 | |||||||||||||

| ID | 130 | 140 | 138 | 200 | 198 | 254 | 250 | 246 | 305 | 300 | 297 | 357 | 350 | 346 | 406 | 400 | 398 | 502 | 500 | 498 | |

| Thickness | 5 | 5 | 6 | 5 | 6 | 5 | 6 | 8 | 5 | 6 | 8 | 5 | 6 | 8 | 5 | 6 | 8 | 6 | 7 | 8 | |

| Coupling OD | 146 | 160 | 162 | 220 | 226 | 274 | 278 | 278 | 325 | 328 | 329 | 377 | 378 | 379 | 426 | 428 | 432 | 529 | 530 | 531 | |

Perforated Round Hole Stainless Steel Sand Control Screen, Pipe Type

From the inside to the outside, the sand control screen is made with the composite sand filtration kits, stainless steel protection kits and other components. The basic tube is API casing or tubing, sand control filters are stainless steel precision porous filter composite materials, made of the whole welded structure. Because of high penetration, high-intensity, high resistance to deformation, high reliability, good corrosion resistance, this sand control screen has excellent performance property. It is the result of a highly effective new technology in mechanical sand control.

Hengmao offers perforated filter tubes for oil field: Oil well sand control screen (anti-sand filter blocks), spiral welded stainless steel filter tube (spiral welded pipe), straight seam welded stainless steel filter tubes.

Perforated straight line pipes are welded with unique spiral distribution formed by spiral welding and greater filter strength. When squeezed in some parts from external, under outside pressure, the forced part will have reduced or closed gap and ensures the reliability of sand control. Made with sophisticated technology, stainless steel filter glove has openings in the side with reduced direct corrosion to the perforated welded sand pipe. Seam gap in the processing ranges between 20 mm-0.7mm. The uniform opening ensures the processing difference is within the error scope allowed - 0.015 mm, also ensures the accuracy of its filter requirements. Using high precision perforating technology, the effective slotting length is the three to five times of common cut seam tube and two to three times of common perforated seam tubes.

Filter Center Tube has unique high precision perforated tube with standard oil and glove tubes. The spiral perforating form of the center tube reduces the opening area of the tube cross section and maintains the strength of the center tube to the maximum. The sand is blocked outside of the perforated screen while the oil, gas or water goes through the perforated opening then enters into the screen.

Features:

Center control tube is API standard tube or oil tube and the high precision perforated filter glove is made of 304 stainless steel materials.

For wells containing H2S, CO2, high-Cl that has special requirements, the center tube can be corrosion-resistant casing or tubing. Screen is acid and alkali resistant and salt corrosion resistant.

Compound Grading Sand Control Screen has adopted unique grade sand control with the surface filter and deep filter combined together to form a double precision. This is the new breakthroughs in the field of mechanical sand control designs. Offering high penetration, high Strength, highly resistant to deformation, high reliability, good corrosion resistance, this is the most effective sand control products at this time.

Perforated Sand Control Tube Specifications:

| Pipe Size | Holes per feet | Size of hole | Perforated Area per Feet |

| 3/4" | 78 | 3/16" | 2.15 |

| 1" | 54 | 5/16" | 4.14 |

| 1-1/4" | 66 | 5/16" | 5.06 |

| 1-1/2" | 78 | 5/16" | 5.98 |

| 2-1/16" | 78 | 5/16" | 5.98 |

| 2-3/8" | 90 | 3/8" | 9.94 |

| 2-7/8" | 102 | 3/8" | 11.26 |

| 3-1/2" | 126 | 3/8" | 13.91 |

| 4" | 138 | 3/8" | 15.24 |

| 4-1/2" | 150 | 3/8" | 16.56 |

| 5" | 162 | 3/8" | 17.88 |

| 5-1/2" | 174 | 3/8" | 19.21 |

| 6-5/8" | 186 | 3/8" | 20.53 |

| 7" | 222 | 3/8" | 24.51 |

| 9-5/8" | 294 | 3/8" | 32.46 |

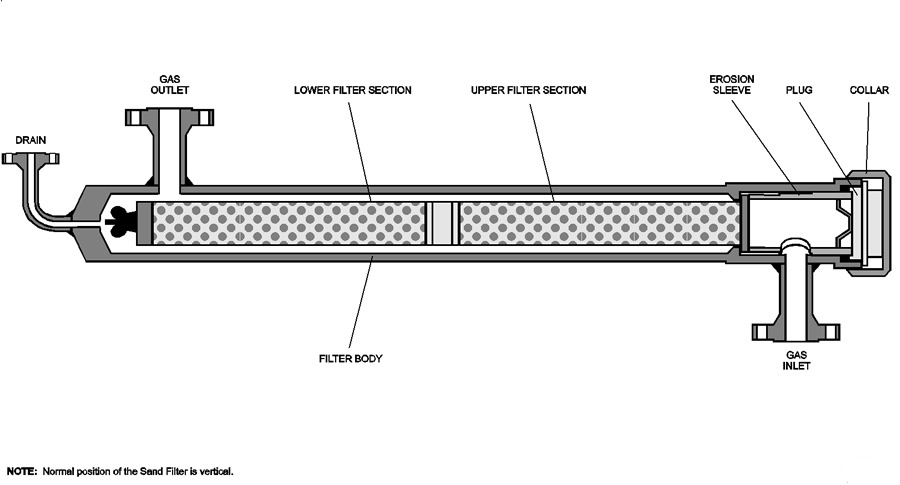

Sand Filter Elements, designed for operation in high-pressure and high-temperature environments while delivering excellent filtration performance, details refering to following:

Wells sand filter mesh and parts:

| Design Pressure | 5000 psig @ 100ºF |

| Design Temperature | 300ºF @ 4880 psig |

| Operating Pressure | 4000 psig |

| Operating Temperature | 275ºF |

| Design Gas Flowrate | 25 MMSCFD |

| Sand Capacity Initial Operating |

154 kg/day 18 kg/day |

| Filtration Ability | 150µ and larger |

| Differential Pressure (Dp) Operating Maximum |

2.5 bar 3.0 bar |

| Dimensions Diameter Length Tan to Seam |

273 mm OD 2208 mm |

| Corrosion Allowance | Nil |

| Materials Shell Head Collar Plug Nozzles Internals Wetted Parts |

API 5LX 52 AISI 4130 API 5LX 52 AISI 4130 INCOLOY 825 SS304/SS316 INCONEL 625 Cladding 3m thick |

| Weight Empty | 940 kg |

Material: The materials ensure long-term durability, chemical resistance, and structural integrity of the well sand filters.

Structures:

This sand filter element comprises a shell and head made from API 5LX 52 and AISI 4130, respectively, offering high tensile strength. The internals are designed from SS304/SS316, which offers excellent corrosion resistance. Special INCOLOY 825 nozzles and INCONEL 625 cladding on wetted parts add an extra layer of durability and chemical resistance. The entire system is designed to operate under high pressures and temperatures, thanks to its robust construction.

Sand filter elements are commonly utilized in:

1,Oil & Gas industry for separating sand and other solid particles from fluids

2,Water treatment facilities for filtration of fine particulates

3,Chemical processing plants where high-pressure and high-temperature operations are commonplace

4,Mining operations for dewatering and particulate separation

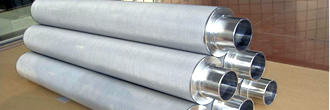

Perforated Tube also popularly used as support pipe / tube and protective pipe for pleated wire mesh filter elements processing as Candle Filter Elements Support Layer

HengMao can offer perforated metal with various patterns.

HengMao can offer perforated metal with various patterns.

Custom designs available. Precise parameters guaranteed.

Hole Patterns including: Round; Rectangular hole; Square; Triangle; Diamond; Hexagonal; Cross; Slotted; and other patterns according to your drawings or application requirement.

Perforated metal tube is widely used as the core filter tube, interior support, out layer protection in making of stainless steel pleated filter elements. Perforated metal sheet can also be processed into disc filters or filter baskets.

Products List

Stainless Steel Wedge Wire Water Well Screen

Stainless Steel Wedge Wire Water Well Screen